COMPUTATIONAL MODELING OVERVIEW

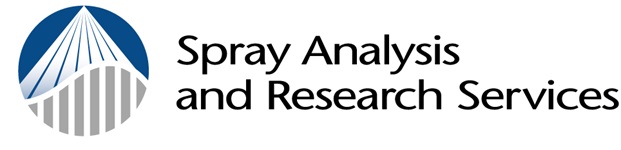

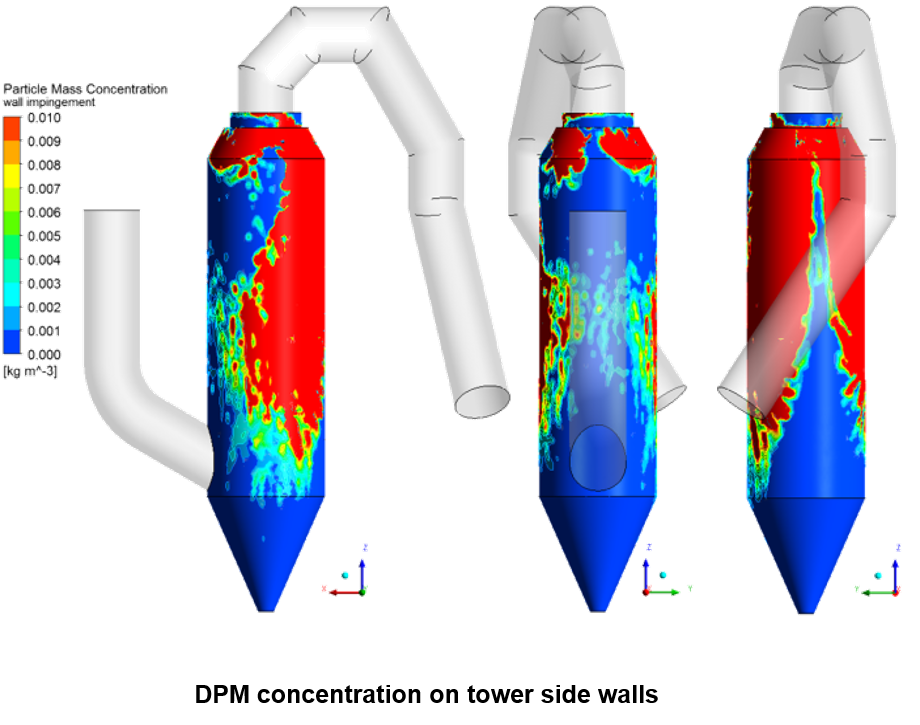

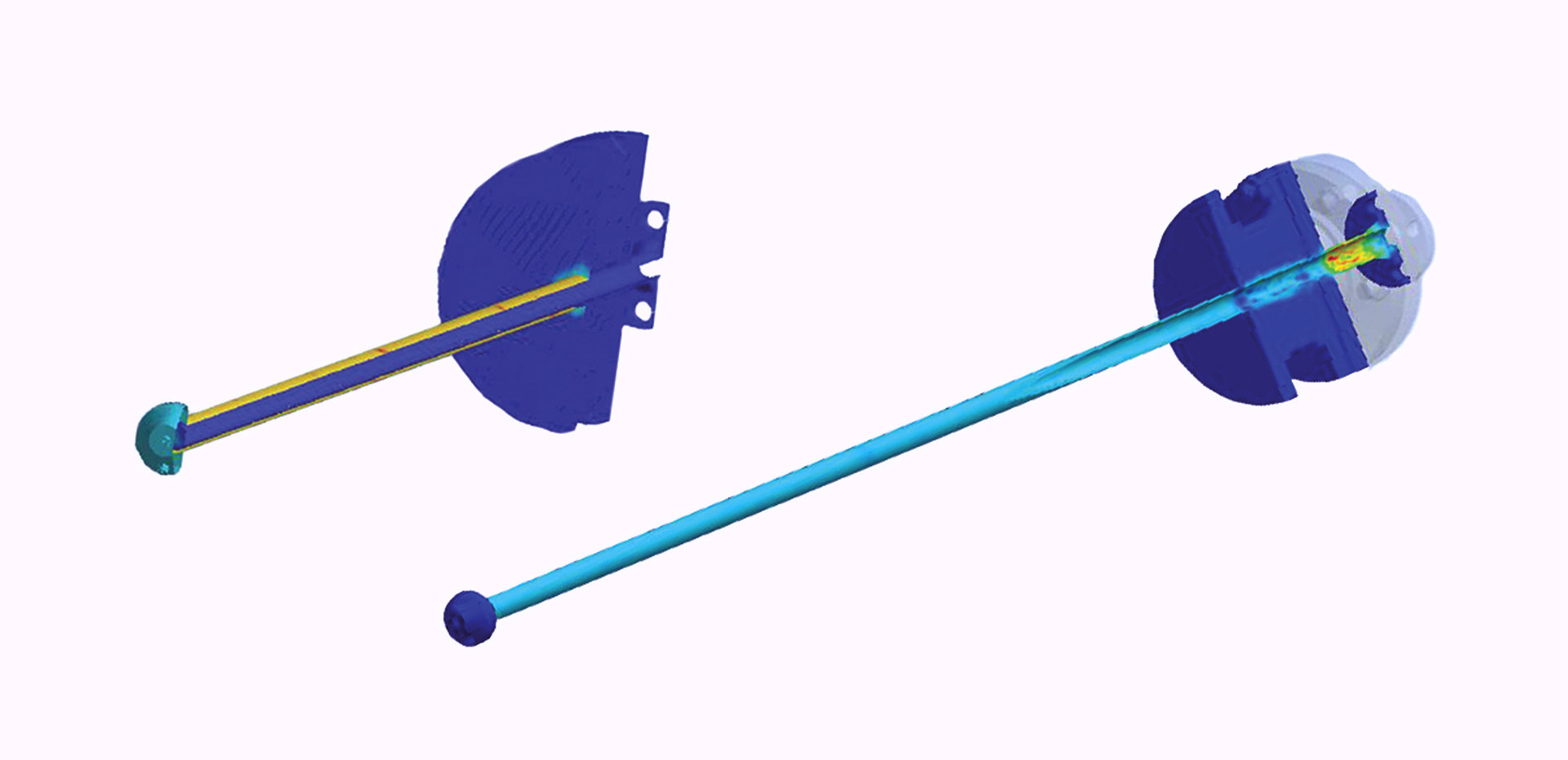

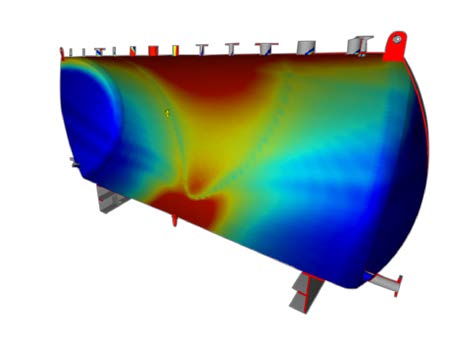

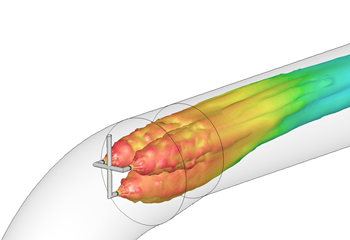

With our computational modeling services, customers benefit from our experience using both gas and fluid flows in an interdependent environment. Furthermore, our library of spray data refines our models giving you the best possible results for any spray-related application.

Computational Modeling Solutions

Browse through our library of modeling case studies to see how we've helped our customers and contributed valuable modeling research to the greater scientific community. Documents provide a full breakdown of our CFD process and how our results provided value and actionable solutions for our customers.